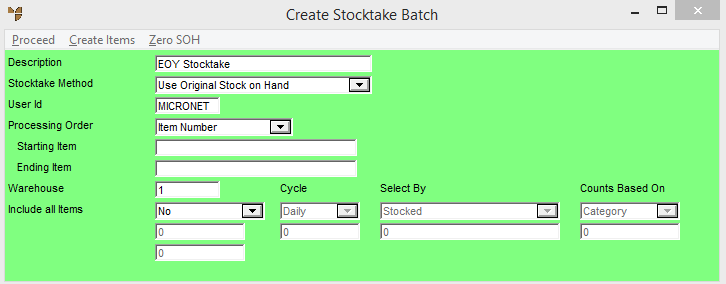

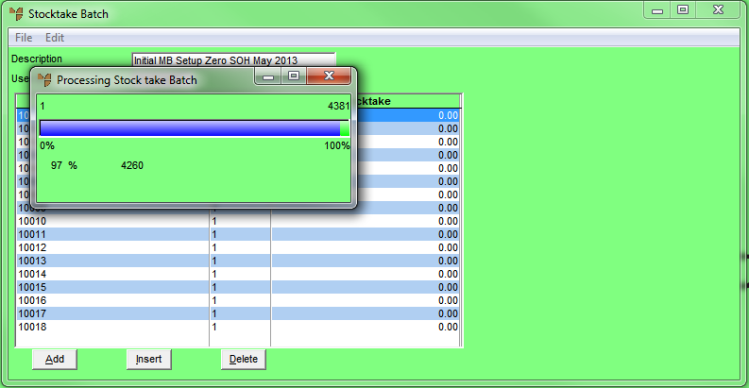

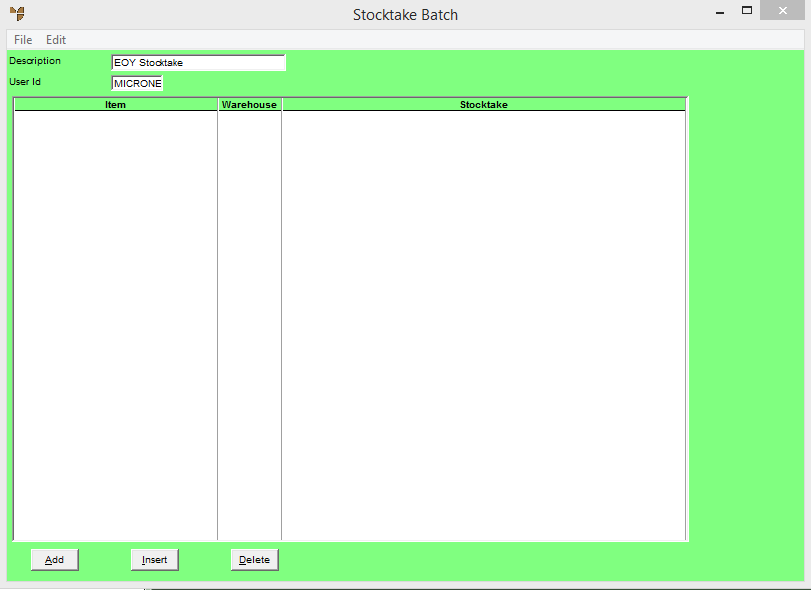

Select INVENTORY | ADJUSTMENTS | STOCKTAKE, enter a Description that clearly identifies the purpose of the stocktake batch (e.g. EOY Stocktake), then press Enter.

|

|

|

Warning Stocktake batches should be created immediately before the physical count begins as Micronet records the stock on hand in the batch at the time the batch is created. Wherever possible, stock should not move while the count is in progress. In cases where stock movements are unavoidable, there must be a clearly defined internal system for tagging bins and recording the stock quantity changes while the count is in progress. Once the physical count is finalised, trading can continue in the warehouse and in Micronet. Because the original stock on hand is recorded in the stocktake batches at the time of creation, the adjustments posted via the batch are not affected by current movements (such as sales and receipts) when trading recommences. |

|

|

Field |

Value |

|

|

Stocktake Method |

Select Use Original Stock on Hand. |

|

|

Processing Order |

The processing order defines the items Micronet creates within the stocktake batch. For example, you can enter a starting and ending bin number to count a section or row in the warehouse. Select the processing order for the stocktake batch:

|

|

|

Warehouse |

Select the warehouse for this stocktake batch. |